Some of you know I’ve been having some minor heat issues while daily driving. My coolant temp gets hotter than I would like it. Not dangerously hot (240 max) but hot enough that I wanted to try my hand at seeing if I can shed a few degrees. The option of a heat reduction hood is out of the budgetary question right now, so I decided, based on a friend’s recommendation, on a Hyline Offroad hood louver. It’s aluminum and comes bare or powder coated. I opted for PC. Ordered from Hyline directly and had it in two days.

I like this design over the Poison Spyder louver because the bolts are welded to the louver itself. I think it’s a much cleaner install. Plus Hyline sends along a steel template that makes locating the few dozen holes that have to be drilled painless.

Things didn’t start off too great. While removing the footman loop off the hood, one of the bolts busted off. Cheap junk. I’ll be ordering a replacement soon.

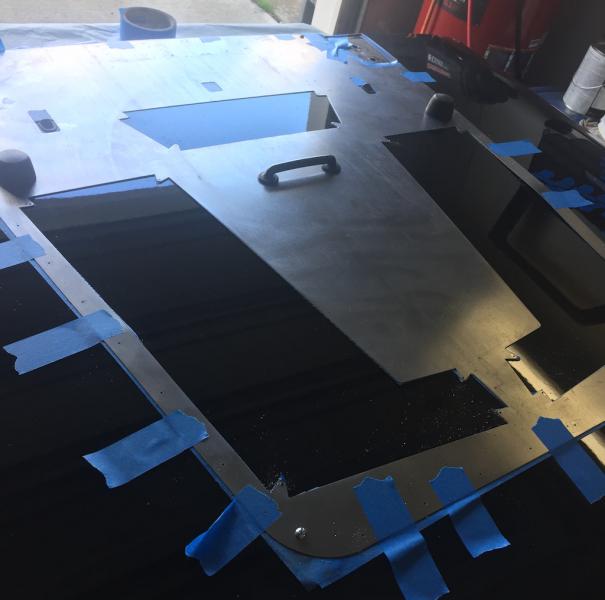

Got the hood off, and with the help from T.J., we got it done in about 3 hours. Some things that are noteworthy.

- The instructions have you drill 1/16″ pilot holes. Have a few extra drill bits on hand.

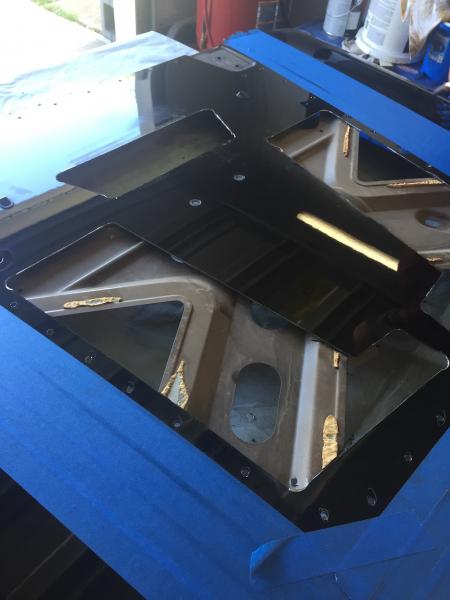

- A good hole saw could not be more important. But even if you are off a little, it’s all hidden.

- The outer sheet metal is glued or double-stick taped to the supporting structure. Took as a minute to figure that out.

- Paint the exposed edges and the hood structure black or some other color.

- Make sure you thoroughly test fit everything. I ran into some issues with the threads on the welded-on studs catching on the holes, making it nearly impossible to secure it flat. I had to remove it, enlarge the holes, and the test fit again. You don’t want any binding at all.

- Take your time, go back and forth between each side, front and rear, securing the studs with the nuts.

Here are a few photos and a short time lapse video.