Removing a hardened bushing with a carbide end mill.

New Machine Day! K. O. Lee Tool & Cutter Grinder

I have had my eye out for a tool and cutter grinder for some time now. But since I like to keep costs to a minimum, the ones I have seen on Fakebook and places are just more than I want to spend. Plus, I need one that will fit in a small space. I kick myself to this day for passing on a nice Brown and Sharp that was at a local auction. When I saw this one come up, I managed to be the winning bidder. It’s going to sit for a while until I can get to it, but it’s here when I am ready to get it prepped for me to learn how to use it.

—-

Check out my blog: https://www.mylilmule.us

Instagram: https://www.instagram.com/mylilmule/

Facebook: https://www.facebook.com/my.lil.mule/

Become a Patreon supporter: https://www.patreon.com/mylilmule

One time donation: https://paypal.me/MyLilMule

T Shirts and such: https://store.mylilmule.us

Etsy Shop: https://mylilmule.etsy.com

Buy me a Pizza: https://www.buymeacoffee.com/mylilmule

Amazon wish list: https://www.amazon.com/hz/wishlist/ls/MBO1LDMVXEWI?sort=priority

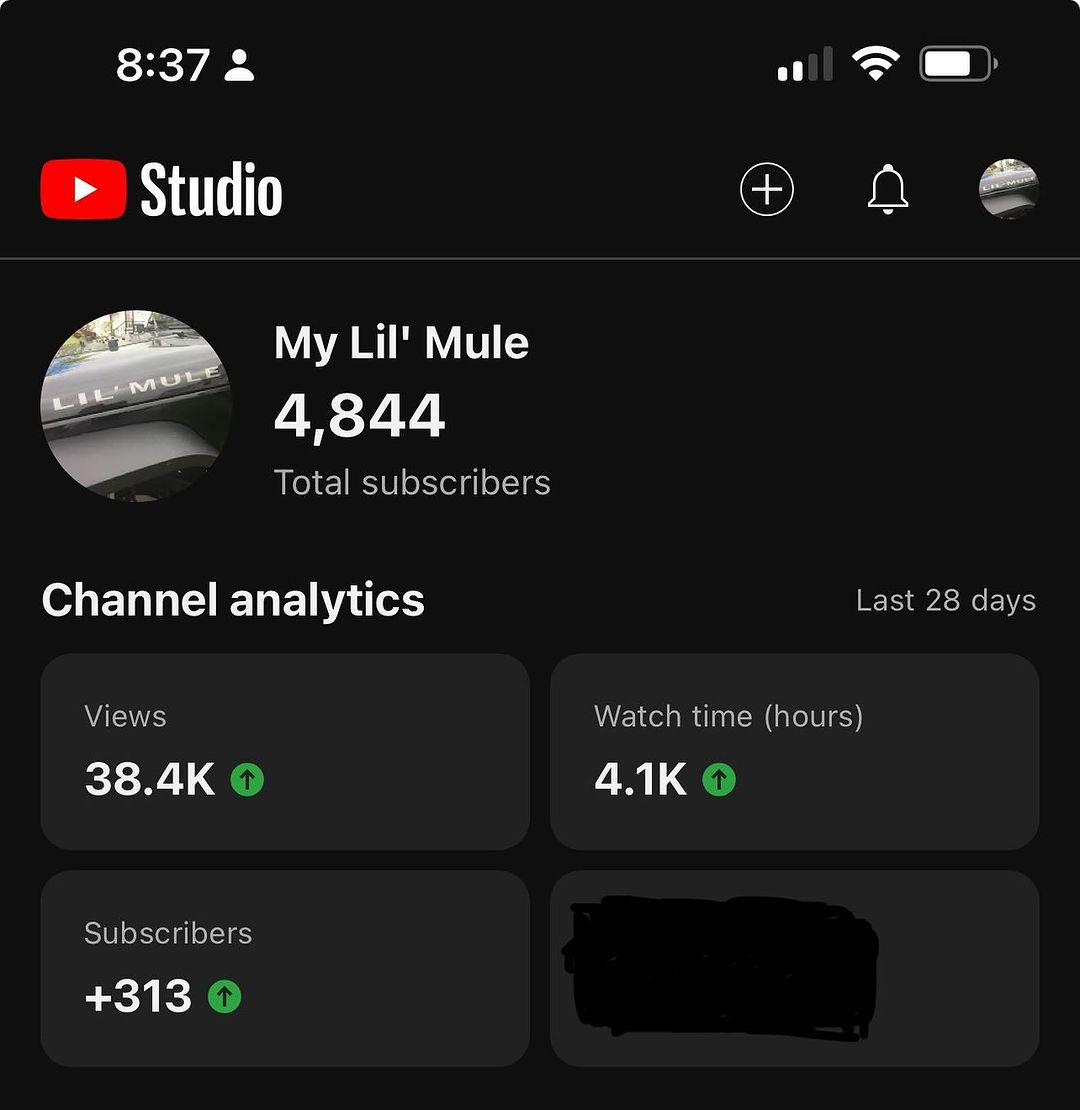

I can’t believe I am this close to 5k subscribers! Crazy to think how the channe

I can’t believe I am this close to 5k subscribers! Crazy to think how the channel has grown so much recently. Love it!

Finally able to put a 25% no exclusions coupon to work. Picked up this Yukon 9 d

Finally able to put a 25% no exclusions coupon to work. Picked up this Yukon 9 drawer cabinet. Using it mostly for storing tooling for the K&T horizontal mill, but there’s some other stuff in it as well. The red cabinet next to it used to hold these items and to say I overloaded it would be an understatement.

Machining a Backplate for a 6-Jaw Chuck for my 1942 South Bend Lathe – Part 1

The shop has acquired a Buck Chuck, 6 inch, 6-jaw chuck that has a back plate for the 1960 South Bend Lathe. I would like to use this on the 1942 South Bend, but that will require a different back plate as the spindle nose threads are different. These aren’t available commercially, so I have no alternative than to make one.

During the process of machining the back plate, I would need something to measure the progress of the internal threads, so I thread gauge is necessary and I will also need to make one of those!

—-

Check out my blog: https://www.mylilmule.us

Instagram: https://www.instagram.com/mylilmule/

Facebook: https://www.facebook.com/my.lil.mule/

Become a Patreon supporter: https://www.patreon.com/mylilmule

One time donation: https://paypal.me/MyLilMule

T Shirts and such: https://store.mylilmule.us

Etsy Shop: https://mylilmule.etsy.com

Buy me a Pizza: https://www.buymeacoffee.com/mylilmule

Amazon wish list: https://www.amazon.com/hz/wishlist/ls/MBO1LDMVXEWI?sort=priority

Installing Tire Clearance Plates on a Jeep JK using the Bestarc BTC500DP Plasma Cutter

My friend Mike has 39″ tires on his Jeep. And they are GREAT for using it off road. However, because the tires are so much wider and bigger, when he turns the wheels all the way to the left or to the right, they rub on the inside of the Jeep’s frame. So we are going to use the opportunity to test out the Bestarc BTC500DP Plasma Cutter that was sent to me by Bestarc to notch out the inside of this frame and then to weld in new plates that will allow his tires to clear.

Affiliate link to the Bestarc BTC500DP: https://amzn.to/3AJwxW6

—-

Check out my blog: https://www.mylilmule.us

Instagram: https://www.instagram.com/mylilmule/

Facebook: https://www.facebook.com/my.lil.mule/

Become a Patreon supporter: https://www.patreon.com/mylilmule

One time donation: https://paypal.me/MyLilMule

T Shirts and such: https://store.mylilmule.us

Etsy Shop: https://mylilmule.etsy.com

Buy me a Pizza: https://www.buymeacoffee.com/mylilmule

Amazon wish list: https://www.amazon.com/hz/wishlist/ls/MBO1LDMVXEWI?sort=priority

Making chips.

Troyke 12″ Rotary Table with Servo Power Feed – Assembly

I came across this 12″ Troyke rotary table at an online auction. But the photos didn’t show what size it was, I was hoping it was a 10″, so I bid on it anyway. Well, it’s a 12″, which is just a bit too big for my mill, and a bit too heavy for me to handle by myself. So I am just going to clean it up and pass it on to its next steward and any profit gained will go back into other shop restoration projects.

The Servo 150 power feed and adapter is pretty cool.

—-

Check out my blog: https://www.mylilmule.us

Instagram: https://www.instagram.com/mylilmule/

Facebook: https://www.facebook.com/my.lil.mule/

Become a Patreon supporter: https://www.patreon.com/mylilmule

One time donation: https://paypal.me/MyLilMule

T Shirts and such: https://store.mylilmule.us

Etsy Shop: https://mylilmule.etsy.com

Buy me a Pizza: https://www.buymeacoffee.com/mylilmule

Amazon wish list: https://www.amazon.com/hz/wishlist/ls/MBO1LDMVXEWI?sort=priority

I need a bigger bad saw.

Troyke 12″ Rotary Table with Servo Power Feed – Disassembly

I came across this 12″ Troyke rotary table at an online auction. But the photos didn’t show what size it was, I was hoping it was a 10″, so I bid on it anyway. Well, it’s a 12″, which is just a bit too big for my mill, and a bit too heavy for me to handle by myself. So I am just going to clean it up and pass it on to its next steward and any profit gained will go back into other shop restoration projects.

The Servo 150 power feed and adapter is pretty cool. I am tempted to take it off this and put it on the Bridgeport Y axis.

—-

Check out my blog: https://www.mylilmule.us

Instagram: https://www.instagram.com/mylilmule/

Facebook: https://www.facebook.com/my.lil.mule/

Become a Patreon supporter: https://www.patreon.com/mylilmule

One time donation: https://paypal.me/MyLilMule

T Shirts and such: https://store.mylilmule.us

Etsy Shop: https://mylilmule.etsy.com

Buy me a Pizza: https://www.buymeacoffee.com/mylilmule

Amazon wish list: https://www.amazon.com/hz/wishlist/ls/MBO1LDMVXEWI?sort=priority