A couple of updates.

Got the housings back from Davis Race Car on Saturday morning and the situation was much better than expected. Jason went ahead and took apart the rear carrier and the pinion to make sure everything was OK. Everything checked out just fine. He did notice the bulkhead connector for the locker was broken, so he replaced that. Put it all back together and installed the stock pinion flange. Even after all of that, the total bill was only $65.13. He could have easily charged me a lot more. Super nice guy. He came highly recommended, and now I know why.

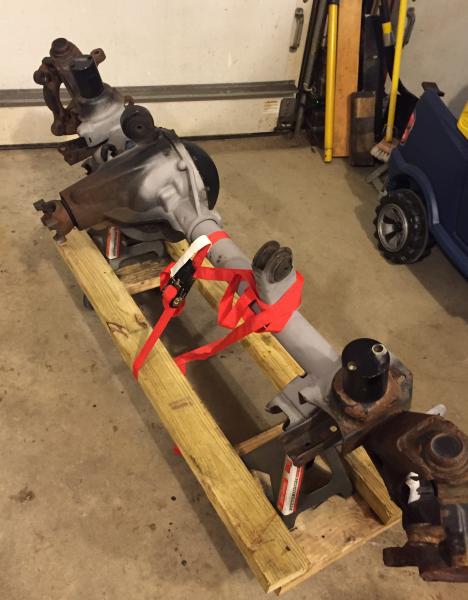

Davis Race Car is about 45 miles from my house. I borrowed a trailer from my old boss for a while to drag the housings from place to place. Went and picked them up, got about 500 feet from my house and CLANK, CLANK! I looked in my side view mirror and saw the front housing hanging over the side of the trailer by the ratchet straps I tied it down with. Oops. I don’t believe it hit the ground, but pretty scary. I lifted it up and put it back on the trailer. I wish I had taken a picture. No harm, no foul. But I’m glad it happened on my street than at 75MPH.

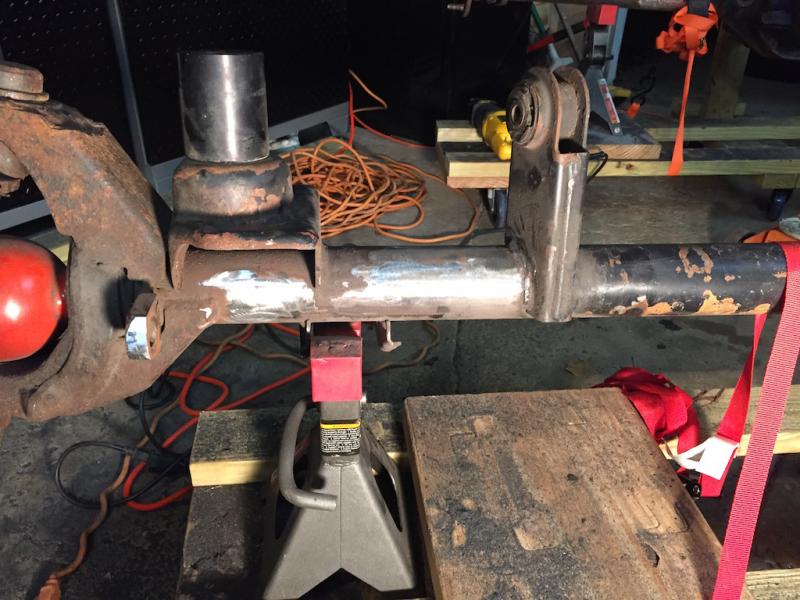

After I got them home, I was looking over the axles, and noticed this:

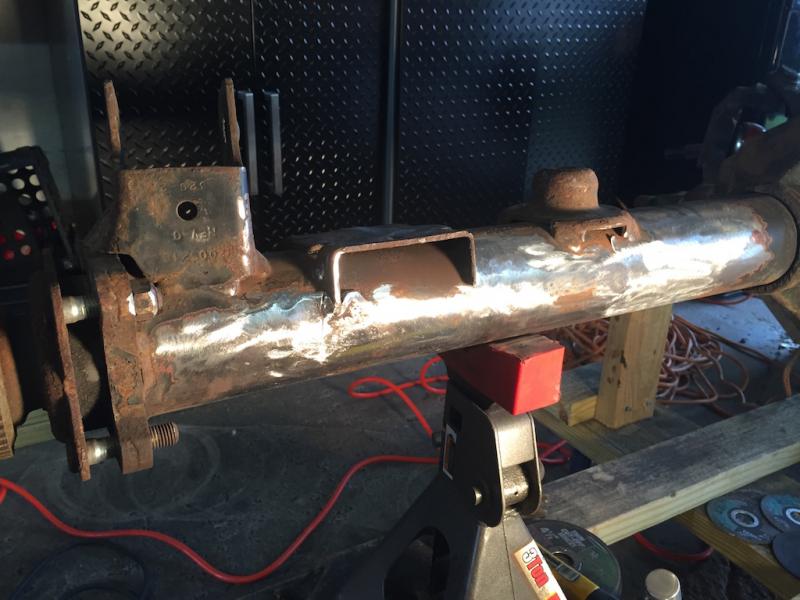

This is where the truss on the driver’s side is welded to the pumpkin. Not sure what happened. It could have been related to the above mishap, but could have also been a cold weld? Texted Andy and took them back to his place Saturday evening.

All fixed! Thanks, Andy!