Well, well, well. What do we have here?

.

.

.

The Series 1 Bridgeport I bought over a year ago is almost completely rebuilt.

The Series 1 Bridgeport I bought over a year ago is almost completely rebuilt. I’ve been making videos along the way. The latest is up on YouTube where I reassemble the top end gears, belts, lions and tigers, oh my!

This little bugger was what was keeping the saddle power feed from working.

This little bugger was what was keeping the saddle power feed from working. It’s a detent plunger that sits under the shaft for the power feed. It was rusted in place. A little penetrating oil (a lot) and some heat (not so much) and an internal pipe extractor and it’s out! The handle moves freely and the power feed is operational! Woohoo!

It’s Alive! The K&T 2 HL had 3 phase power now and starts right up!

New to me machine moving day!

A little #BeforeAndAfter for your Friday.

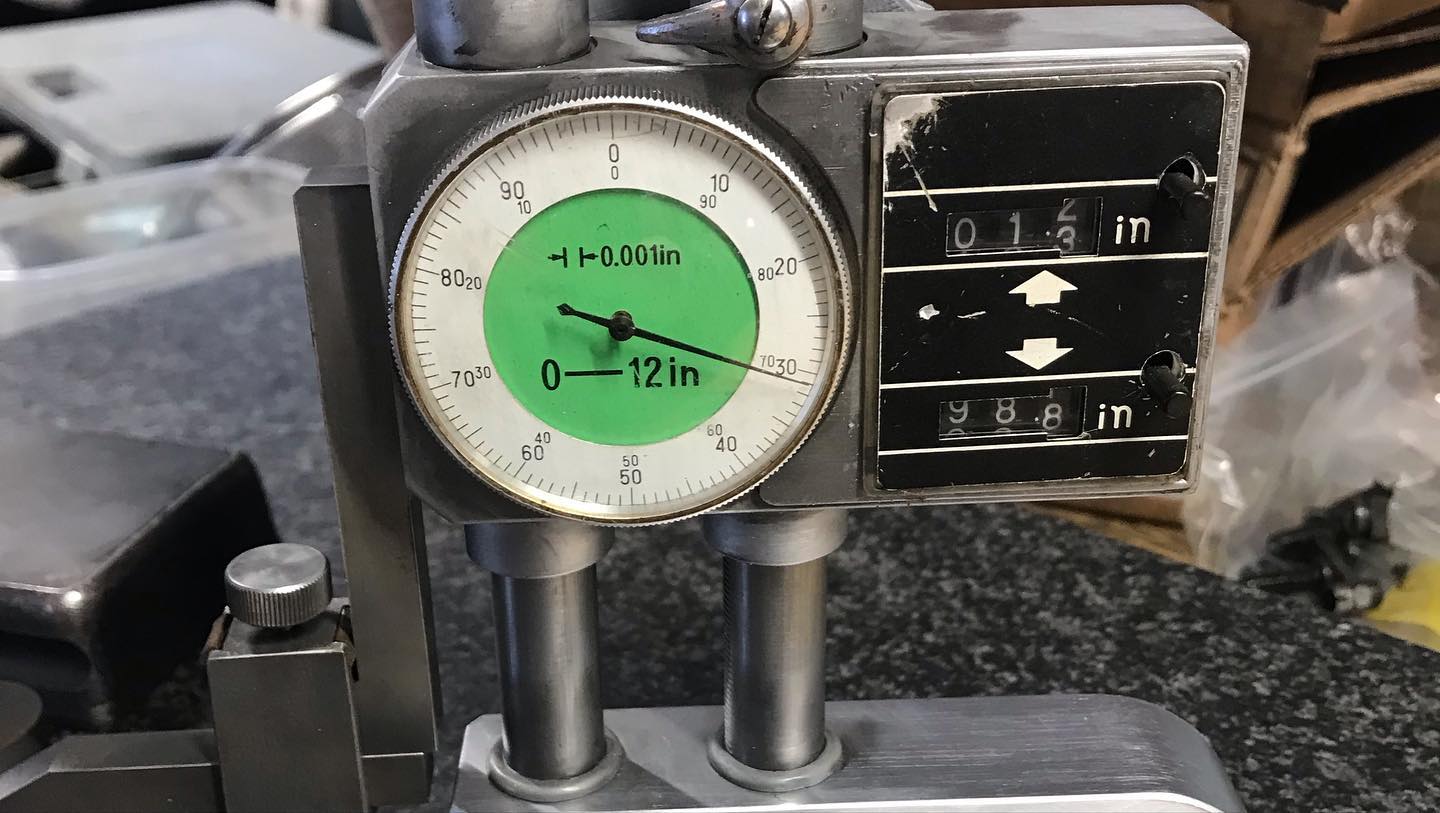

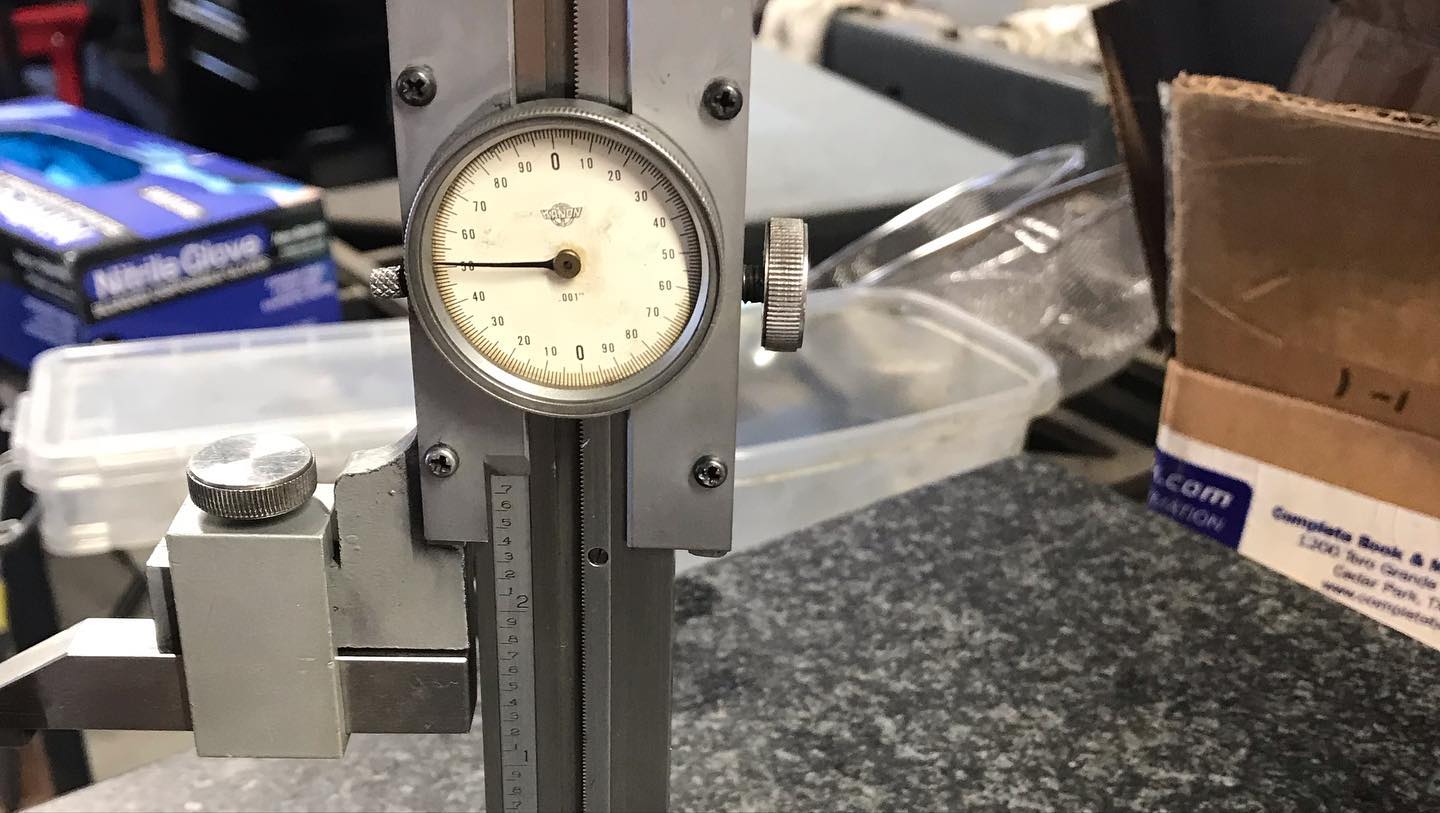

A little for your Friday. I bought these two height gauges along with two others at auction. They were pretty filthy. Nothing a little elbow grease can’t solve. Still need to get the crystal for the one. But they are both accurate and working. Money well spent. Now, I just need to decide if I want to part with any of them!

.

.

.

.

Getting the saddle back on the knee

Getting the saddle back on the knee also necessitated putting the Bijur oil metering block and oil lines back in place.

The Bijur one-shot lubrication pump is back on the Bridgeport knee.

The Bijur one-shot lubrication pump is back on the Bridgeport knee. Over all, it was in decent shape and went back together easily.

The knee to the Bridgeport mill has been installed back on the base.

The knee to the Bridgeport mill has been installed back on the base. Making progress!

.

.

.

.

.

.

.

.

The swarf inside the knee on this Bridgeport is nuts.

The swarf inside the knee on this Bridgeport is nuts. Has to be 6 inches or more deep. Cleaning this is going to be hazardous. 😂 I might need to find me some kevlar gloves. LOL!

.

.

.

.

.

.

.

.