Having a little fun with the shaper on Easter Sunday.

This “fixture plate” was attached to the table of a drill press I bought at an a

This “fixture plate” was attached to the table of a drill press I bought at an action. The holes weren’t very square to the plate, but I figure it could be useful in the future, so I cleaned it up with the fly cutter I made a couple years ago.

I’ve been working on repairs to this Kearny & Trecker Universal Milling Head for

I’ve been working on repairs to this Kearny & Trecker Universal Milling Head for a long time. I am finally ready to get it back together. Check out the link in my bio to the YouTube video of part 1.

.

.

.

.

.

.

.

.

Thanks, this will come in handy. Appreciate the support!

Super excited to find this Union Tool Chest Works tool box on Facebook. Unfortun

Super excited to find this Union Tool Chest Works tool box on Facebook. Unfortunately, it is missing the front cover and needs a lot of TLC. I hope to have a new front cover made, but finding a lock for it might be difficult to impossible. Once I clean it up, I’ll decide if it needs to be refinished completely or only some new wax. I did some research and am confident this was made between 1916 and 1918!

.

.

The shop is going to be a lot cooler this next summer. And maybe a bit warmer th

The shop is going to be a lot cooler this next summer. And maybe a bit warmer this winter. Taking advantage of the @menardshomeimprovement 12% rebate!

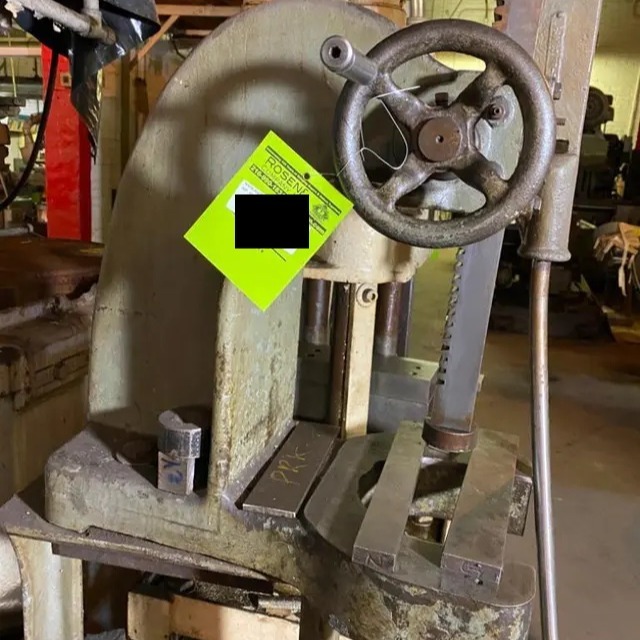

A little before and after of a Famco 13R 4 ton arbor press I recently bought at

A little before and after of a Famco 13R 4 ton arbor press I recently bought at auction for a song. Power washed it, stripped the paint, new rattle can paint job and a little paint pen for the lettering. If I subtract for how much I sold my Chinese import 2 ton press, I’m into this for about $40.

My first try at machining a splined shaft. This is a test piece in Delrin before

My first try at machining a splined shaft. This is a test piece in Delrin before committing to some of the limited amount of 1045. Going to be a fun project to complete. Hopefully a YouTube video on making this will drop Sunday. 🤞🏻

Pulled the power feed gearbox from the K&T today. Could be worse. Was hoping for

Pulled the power feed gearbox from the K&T today. Could be worse. Was hoping for better. This is why you should NEVER use water based coolant on these old machines. I wonder if @evapo_rust would like to sponsor a video and donate a 55 gallon drum of product to the cause? 😂😂

.

.

.

I wish I could remember who pointed me in the direction of this stuff, so I coul

I wish I could remember who pointed me in the direction of this stuff, so I could at least give some credit. This is EPDM Rubber Trim from McMaster (Part 5/8” wide x 3/4” high. Fits perfectly in the T slot of the Bridgeport. 10 feet was only $33.20. No more digging chips out of the slots or dropping a drill bit in there either. Pulls right out when you need to use them.

.

.

.