The eagle has landed!

When it won’t fit in the band saw vise. Just a little stock removal.

I needed to make a 6” hole in some .250” plate. I don’t have a plasma cutter. An

I needed to make a 6” hole in some .250” plate. I don’t have a plasma cutter. And I suck at using a torch. A friend recommended a Harbor Freight hole saw and run it slow with lots of oil. Worked like a champ and the hole saw is in great shape! That squeal though! 😂😂😂

Tomorrow’s YouTube video is now LIVE and AD FREE on my Patreon (link in the bio)

Tomorrow’s YouTube video is now LIVE and AD FREE on my Patreon (link in the bio) along with a special EXTENDED CUT edition.

I spent a bunch of time machining this cast iron straight edge from Denis Foster

I spent a bunch of time machining this cast iron straight edge from Denis Foster for an upcoming class on machine scraping. First time ever machining something like this, especially the odd shapes. I got a lot of help from the maker, and others, and it came out great! There’s a link in my bio to the first of the two part video series I have up on YouTube.

.

.

.

.

.

.

.

.

For $10, why not?

Some of the equipment at the Illinois Railway Museum’s machine shop in the Steam

Some of the equipment at the Illinois Railway Museum’s machine shop in the Steam Locomotive Shop.

Got the motor with new bearings into the K&T 2HL. Can’t hear a thing!

Doing what I have to do to make sure “tick tick tick” doesn’t go “boom!” Looks l…

Doing what I have to do to make sure “tick tick tick” doesn’t go “boom!” Looks like I had a bad bushing in the spindle pulley. Simple and cheap fix.

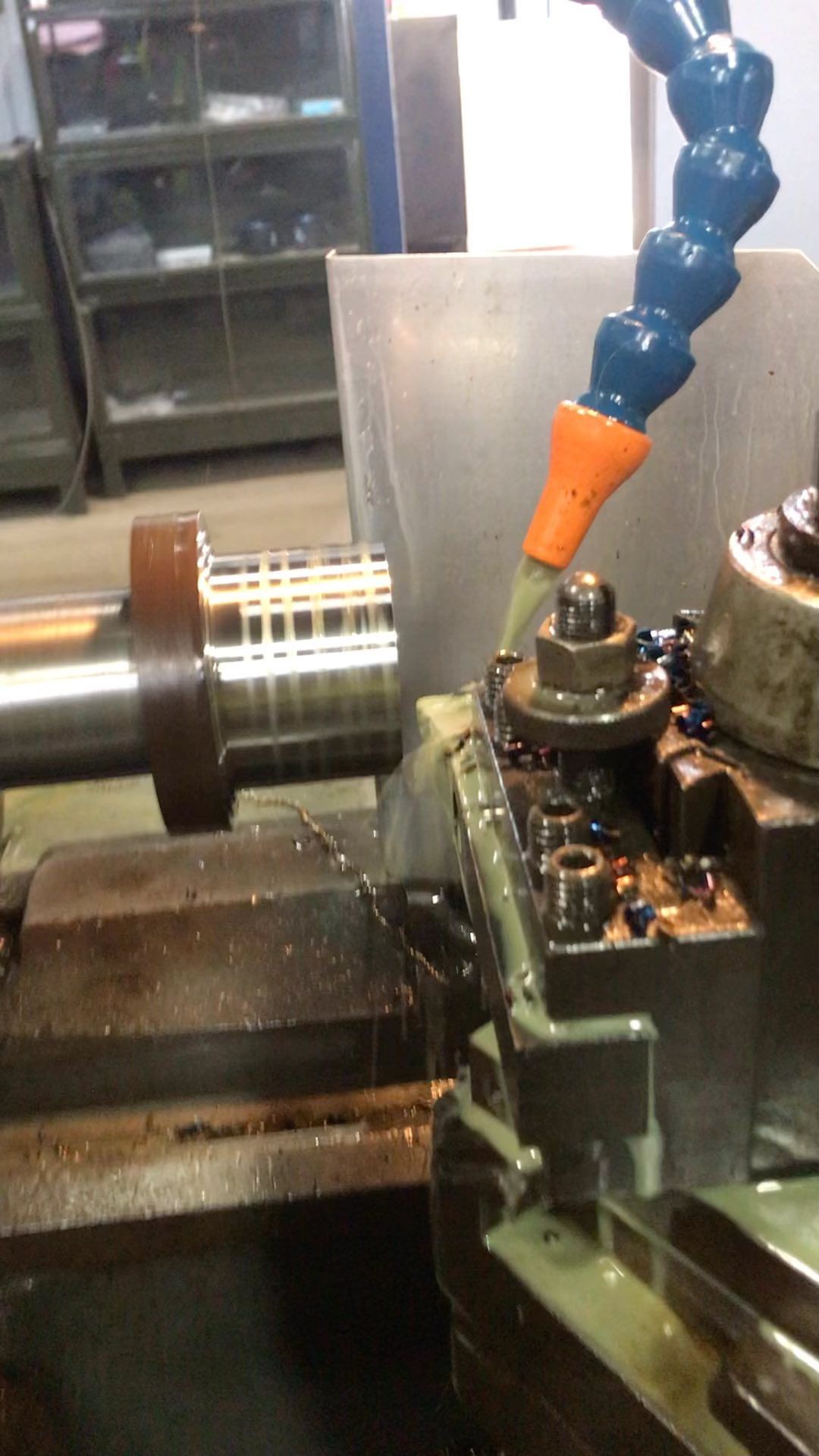

Finally finished machining the parts I needed for my 13″ South Bend steady rest.

Finally finished machining the parts I needed for my 13″ South Bend steady rest.

Source