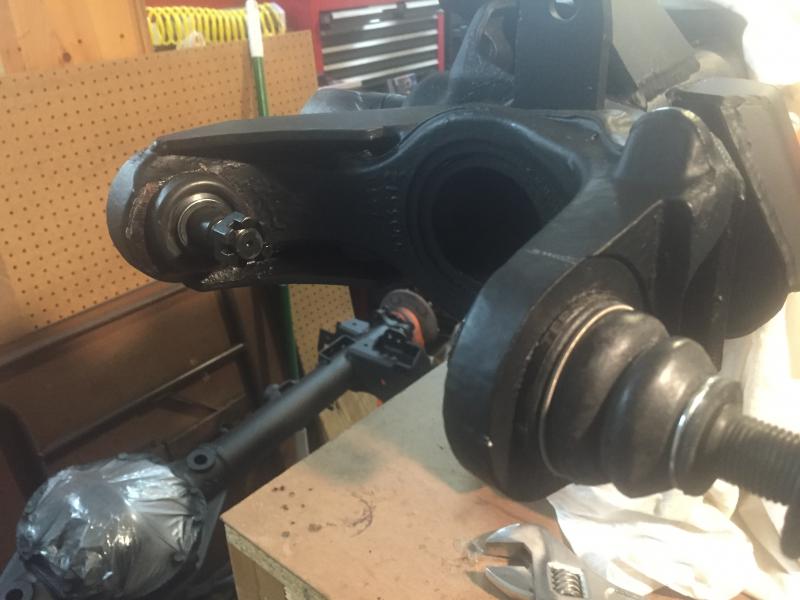

Took all the stuff, including the axle housing to Rob’s place for the axle install. He has a nice 2 1/2 stall garage to work in. I think the kitchen sink is in one of those boxes.

This took a lot longer than I had estimated. I figured around 4 hours, ended up taking 12. Ran into a couple of hiccups.

A high school friend, Peter, had come over to help but had to leave early. Sam also came over and was a huge help.

Don’t have a lot of photos, but hope to have a time lapse video in a few days.

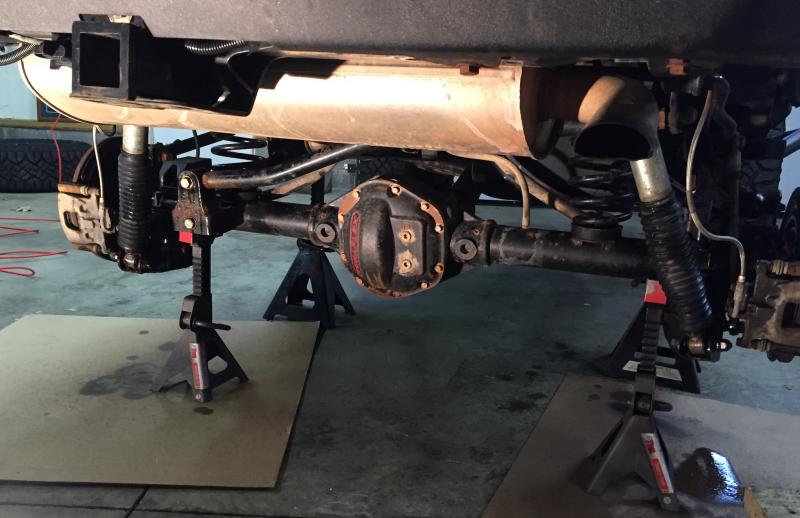

The finished product:

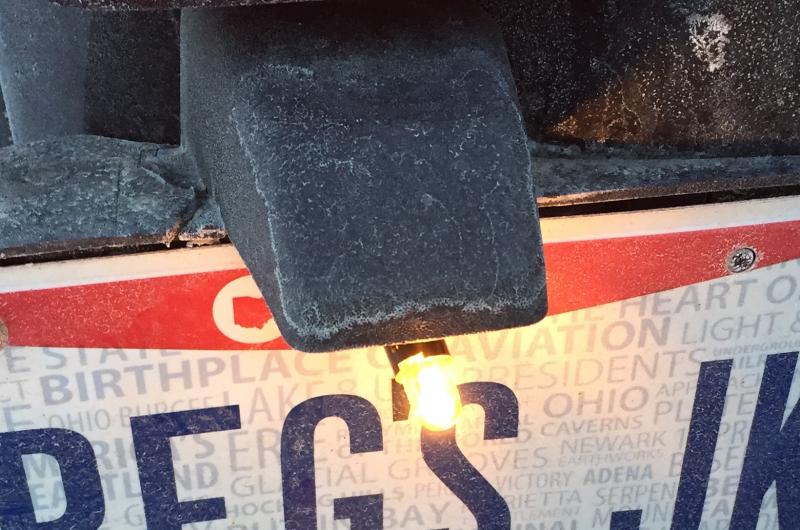

After using a ProCal to set the final drive gear ratio, took it for a test drive I took this on the way home. Tracks with the GPS. Looks about right!

Here were the few quick easy steps we took to swap the axles:

- Put wheel chocks in front/behind front wheels

- Support frame on jack stands.

- Remove wheels

- Drain gear oil.

- Support axle on jack stands with cart.

- Remove calipers – support with bungee

- Remove brake rotors.

- Disconnect speed sensor plugs.

- Remove rear drive shaft from pinion. Support with bungee

- Remove axle flange nuts (4 each side)

- Connect slide hammer to lug bolts and remove rear shafts with parking brake assemblies

- Plug the housing tube ends with rags.

- Disconnect breather hose

- Disconnect parking brake cables.

- Remove lower shock bolts.

- Remove lower track bar bolt.

- Remove lower sway bar link bolts.

- Remove upper control arm bolts.

- Remove lower control arm bolts.

- Take disconnected housing off jack stands and on a floor jack to get it out of the way.

- Swap spring wedges, retainers and springs to new housing.

- Swap bump stops to new housing.

- Remove speed sensors from old shafts

- Remove parking brake assemblies and dust shields from old housings

- Install dust shields and parking brake assemblies on new shafts.

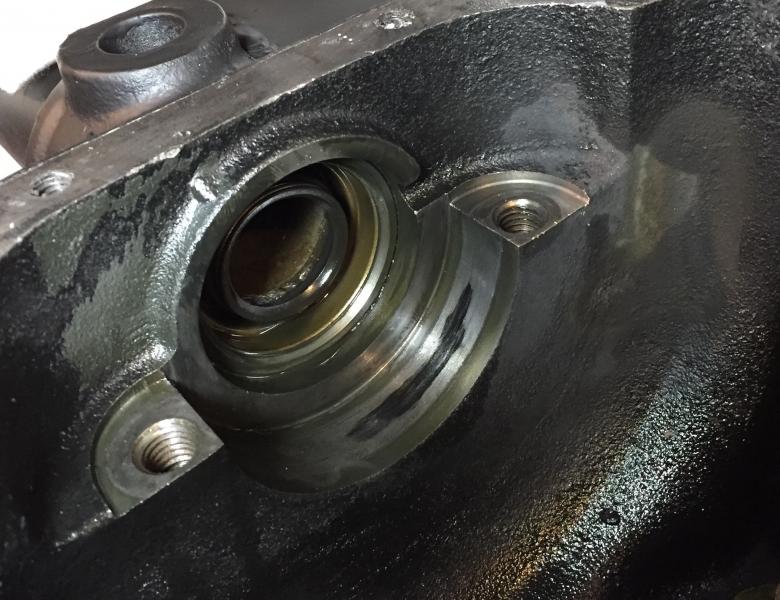

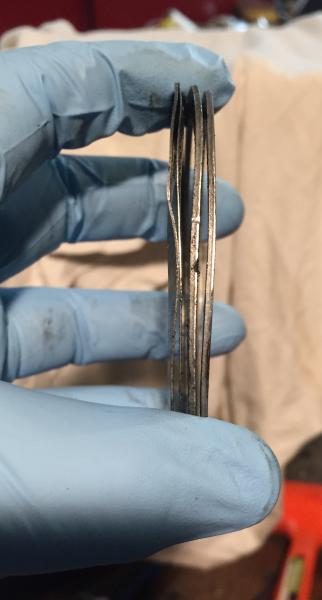

- Remove old Rubicon shafts bearing races and replace with new races.

- Put High Temp Bearing Grease in new shaft bearings.

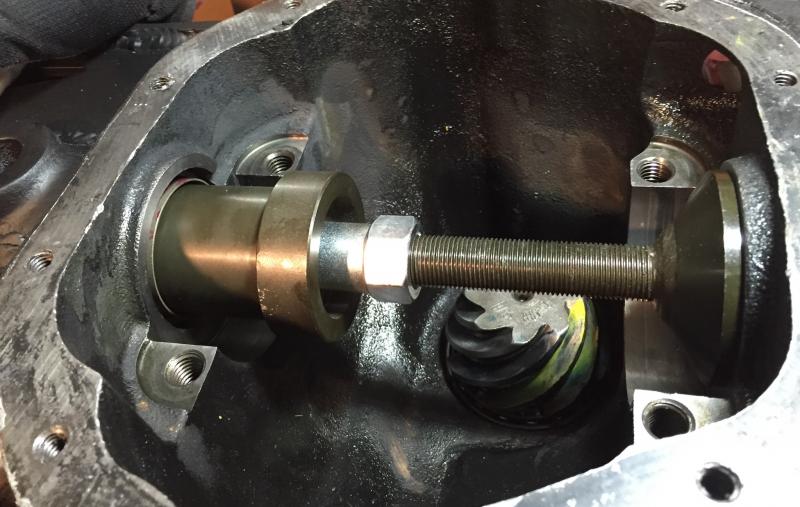

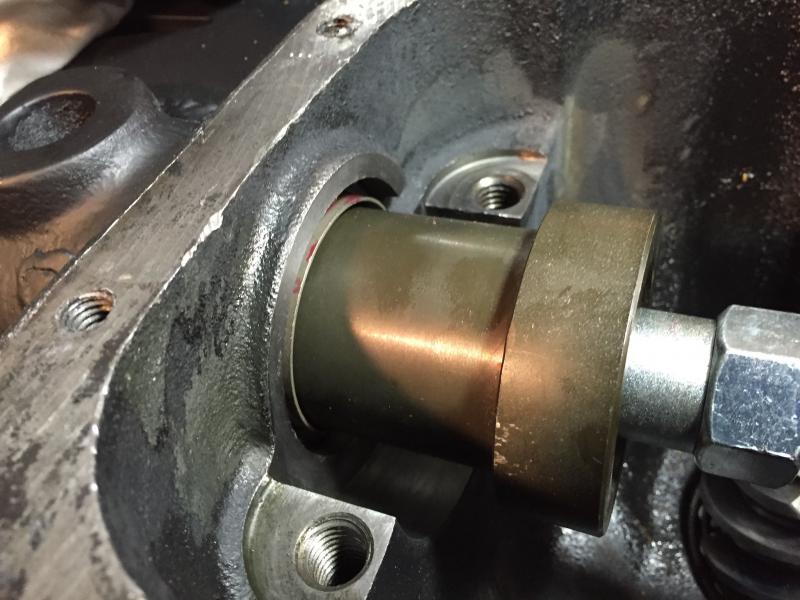

- Slide new shafts into new housing. Tighten 4 axle nuts

- Install speed sensor in new shafts

- Slide new housing into place under the Jeep

- Install CA bolts – hand tight

- Install Track bar bolt – hand tight

- Install sway bar bolts

- Install lower shock bolts

- Connect speed sensor plug

- Install parking brake cables

- Connect diff breather hose

- Install brake drums

- Install brake calipers

- Remove old diff cover

- Clean differential face

- Spray out inside of diff with brake cleaner

- Install Lube Locker and diff cover

- Put new housing on axle cart and slide into place.

- Fill new axle with gear oil

- Remove axle cart

- Jack up Jeep and remove frame jack stands

- Set axle housing on jack stands on ground.

- Torque CA bolts

- Torque TB bolt

- Reconnect rear drive shaft

- Replace wheels

- Lower vehicle to ground

- Check axle centering – adjust track bar if necessary

- Use ProCal to set gear ratio to 4.88

- Drive it.