I saw this old compressor on Fakebook marketplace and when I went to go buy it, the seller just gave it to me. That was a clue that it needed work.

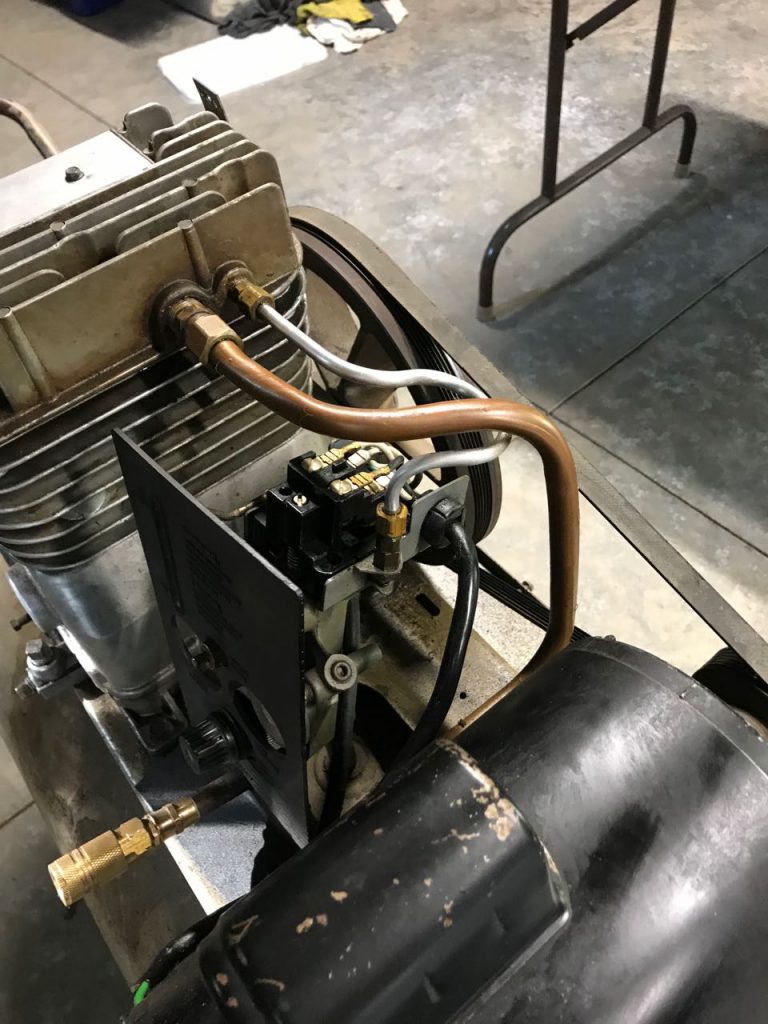

It appears to be an old Sears single stage compressor, probably maxes out at 135psi. But it had a 3 horsepower motor attached to it that ran off 220v, so it should have some guts to it. I put a plug on it and the motor ran great and the tank held air. It wouldn’t shut off, so I ordered a new pressure control switch.

But the thing was covered in oil. I was sure it needed new seals and gaskets. When I drained the air, the tank had some pretty rusty water in it and there was oil in the water. Another sign that there was a bad piston seal. I went ahead ordered new gaskets and piston seals. I also needed to order new flapper valve plates. Once I got it apart, one of them was broken. I started cleaning some of it. I wish I had a parts washer, it would make this a lot easier.

So far, I only have about $100 into it for the parts I ordered. I shouldn’t need anything else. I’ll clean up the tank and give it a fresh coat of paint. If it all goes back together, I’ll use this as my shop compressor and hook it into some permanent piping with outlets around the walls.