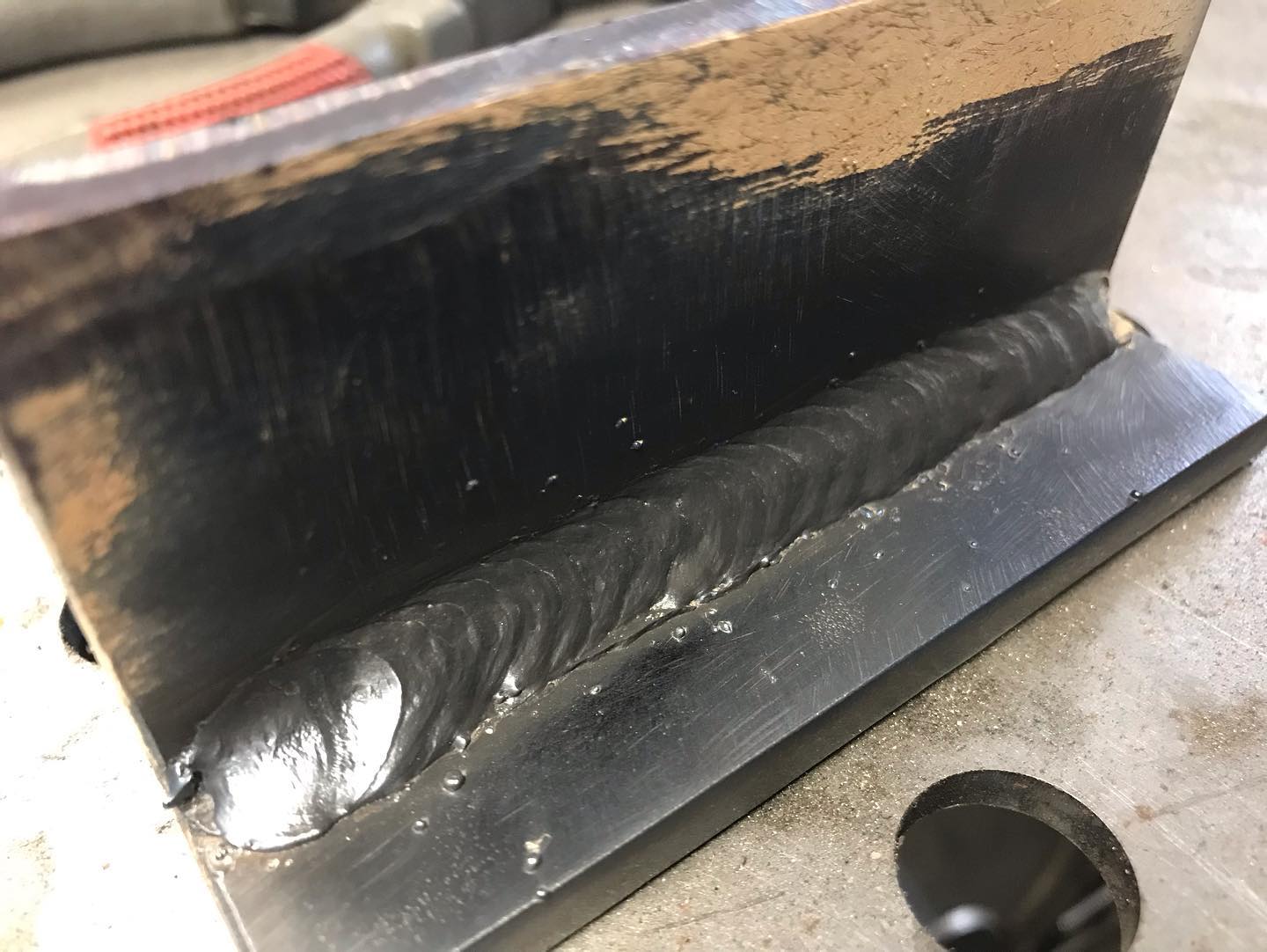

Need a tool, make a tool. The welds are less than pretty, but I needed to bang this post driver so I could set some heavy t-posts for the firewood pile. Didn’t want to buy one and this is all scrap material I had in the shop.

I was sent a torch mounted amperage control to try out and review. I published a

I was sent a torch mounted amperage control to try out and review. I published a video on how I set it up and my first attempts at getting comfortable with it. Check the link in my bio for the video.

.

.

.

.

.

.

.

.

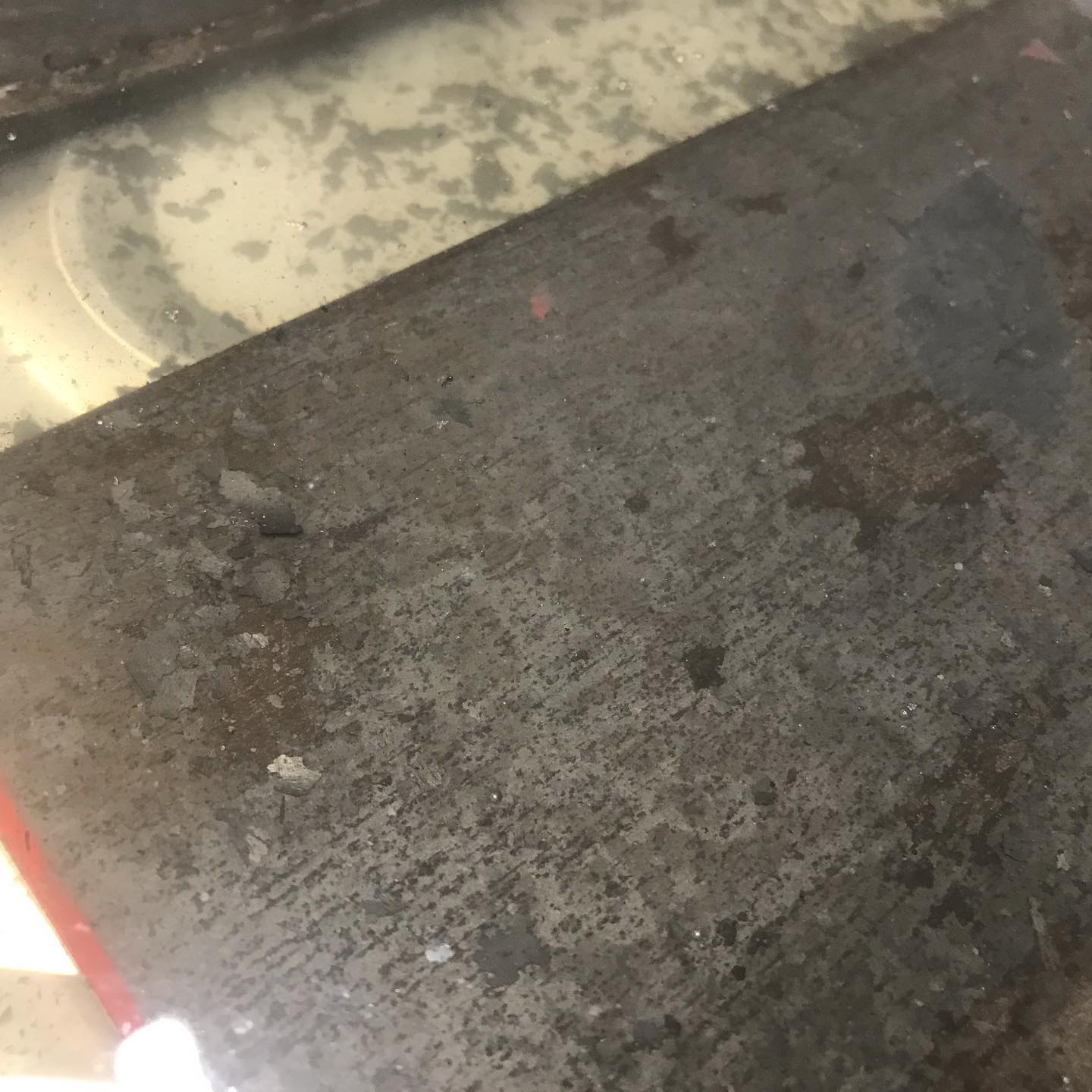

I think I have finally figured out the porosity issues

I think I have finally figured out the porosity issues I am having with my @hobartwelders 175 MIG welder when using ER70S-6 solid wire and C25 gas. That aluminum block in the second photo is the gun connector. It and the brass fitting on the gun, third and forth, had corroded so badly that I am sure there is an air leak. Trouble is, that part is no longer available. So until the Bridgeport is up and running so I can make a new one, going to have to resort to E71T-11 flux core. It welds nice, but the smoke and fumes is a pain when welding indoors.

.

.

.

.

Only took me 3 years to finish this little cabinet for our downstairs powder room.

Only took me 3 years to finish this little cabinet for our downstairs powder room.

.

.

.

.

I recently bought a Bridgeport vertical mill that is in need of some work.

I recently bought a Bridgeport vertical mill that is in need of some work and repairs. The milling head was not attached to the base. I wanted to get it put back on, but it weighs over 100 pounds (without the motor) and the bolts are tricky to line up. I have seen other videos from Mr. Pete and H&W Machine where they used a special tool to make removing and installing the head much easier. I decided to make my own version of the tool.

•

•

•

•

•

I tried giving the white vinegar soak another try.

I tried giving the white vinegar soak another try and see how effective it is for removing mill scale. Wow. It didn’t work this well last time I did. I’m a believer.

.

.

.

.

Welding god or God welder?

I used some @bluedemonweld Aluminum Bronze TIG rod to repair the worn splines on this shaft

I used some @bluedemonweld Aluminum Bronze TIG rod to repair the worn splines on this shaft from the power feed clutch on an 80 year old lathe. I have never done something like this before, and I think it went well and came out OK. Check the link my bio for a video.

•

•

•

•

•

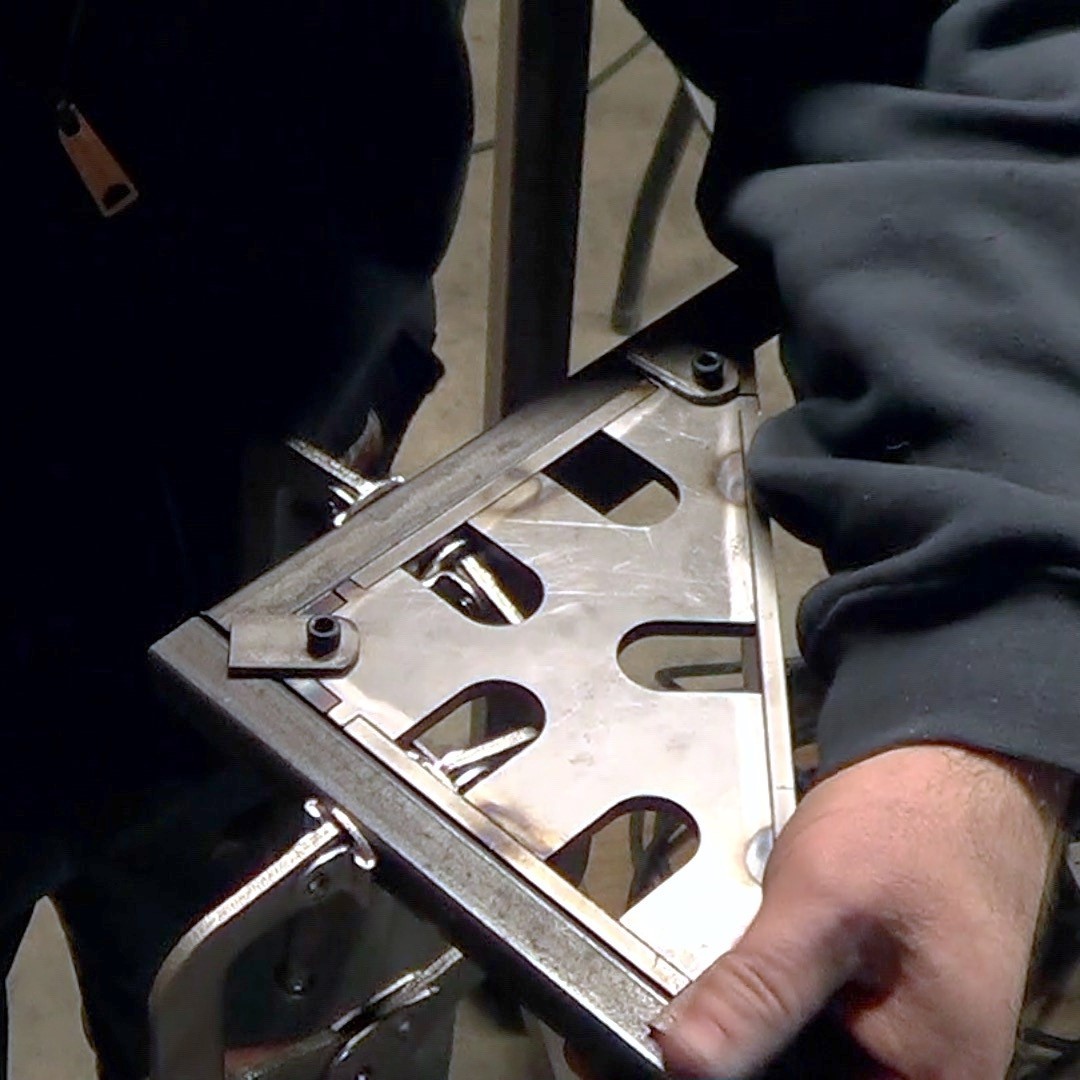

I made a second version of a welding square.

I made a second version of a welding square. These were drawn up in Fusion 360, exported as DXF files, and then sent to a CNC water jet controller and cut from .250 steel.

•

•

•

•

•

Welding squares

Inspired by a product I have seen online and used in other YouTube videos, I set out to make my own welding square. I learned a little Fusion 360 and designed this small 8″ welding square. I was fortunate enough to have this cut out on a water jet at a local maker space. Used the Primeweld TIG 225x to weld it up.