I was sent a torch mounted amperage control to try out and review. I published a video on how I set it up and my first attempts at getting comfortable with it. Check the link in my bio for the video.

.

.

.

.

.

.

.

.

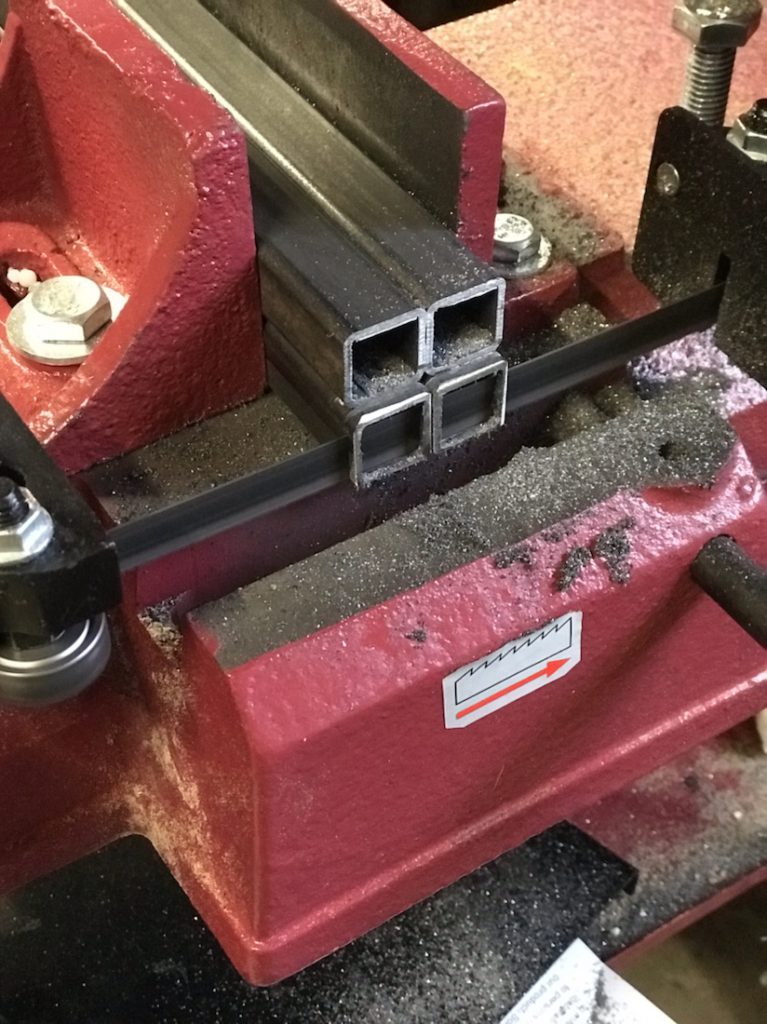

I recently bought a Bridgeport vertical mill that is in need of some work.

I recently bought a Bridgeport vertical mill that is in need of some work and repairs. The milling head was not attached to the base. I wanted to get it put back on, but it weighs over 100 pounds (without the motor) and the bolts are tricky to line up. I have seen other videos from Mr. Pete and H&W Machine where they used a special tool to make removing and installing the head much easier. I decided to make my own version of the tool.

•

•

•

•

•

I used some @bluedemonweld Aluminum Bronze TIG rod to repair the worn splines on this shaft

I used some @bluedemonweld Aluminum Bronze TIG rod to repair the worn splines on this shaft from the power feed clutch on an 80 year old lathe. I have never done something like this before, and I think it went well and came out OK. Check the link my bio for a video.

•

•

•

•

•

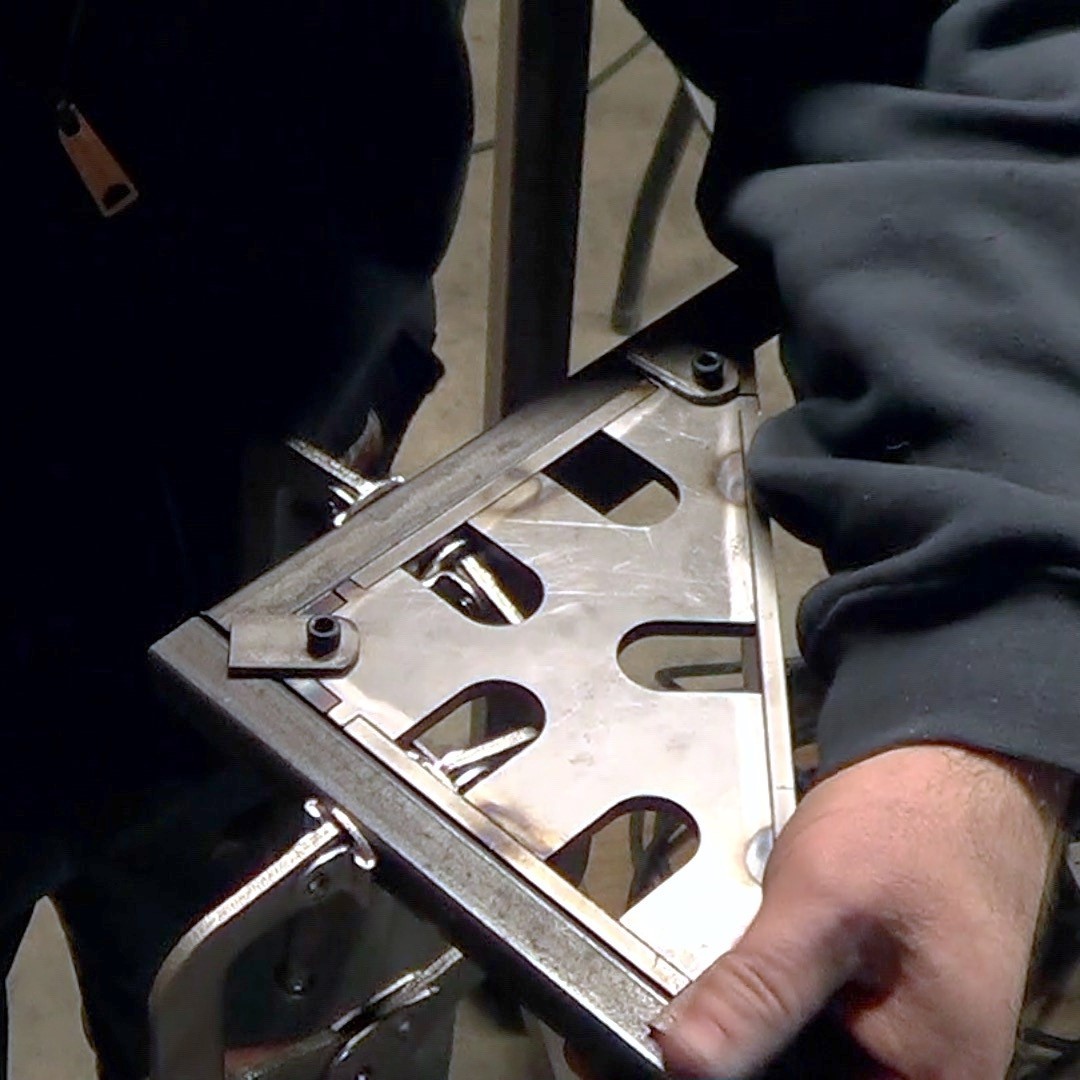

I made a second version of a welding square.

I made a second version of a welding square. These were drawn up in Fusion 360, exported as DXF files, and then sent to a CNC water jet controller and cut from .250 steel.

•

•

•

•

•

Welding squares

Inspired by a product I have seen online and used in other YouTube videos, I set out to make my own welding square. I learned a little Fusion 360 and designed this small 8″ welding square. I was fortunate enough to have this cut out on a water jet at a local maker space. Used the Primeweld TIG 225x to weld it up.

Don’t tell the cops!

Don’t tell the cops! ;)

I was making some tack welds on a project the other day and it was awkward to reach some of the areas with the torch and reach the foot pedal at the same time. I installed the finger trigger on my TIG torch to make these operations easier. I made a video of the results and some explanation of what how some of the controls on the welding machine are affected.

•

•

•

•

•

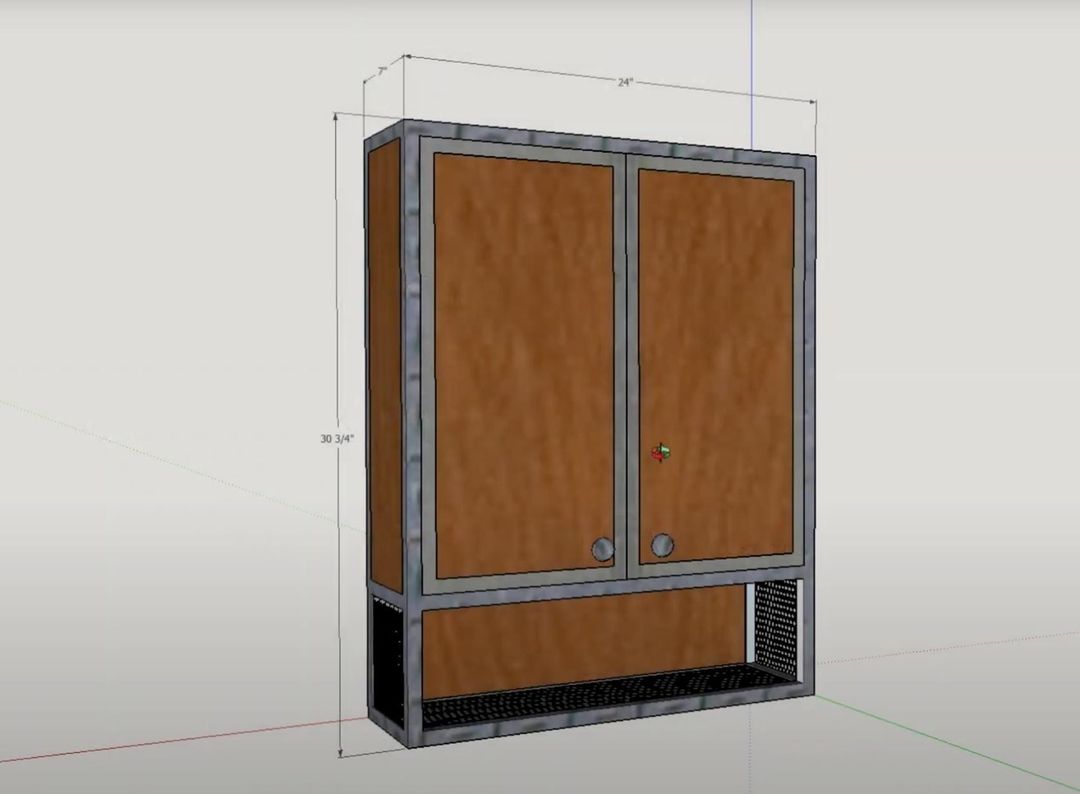

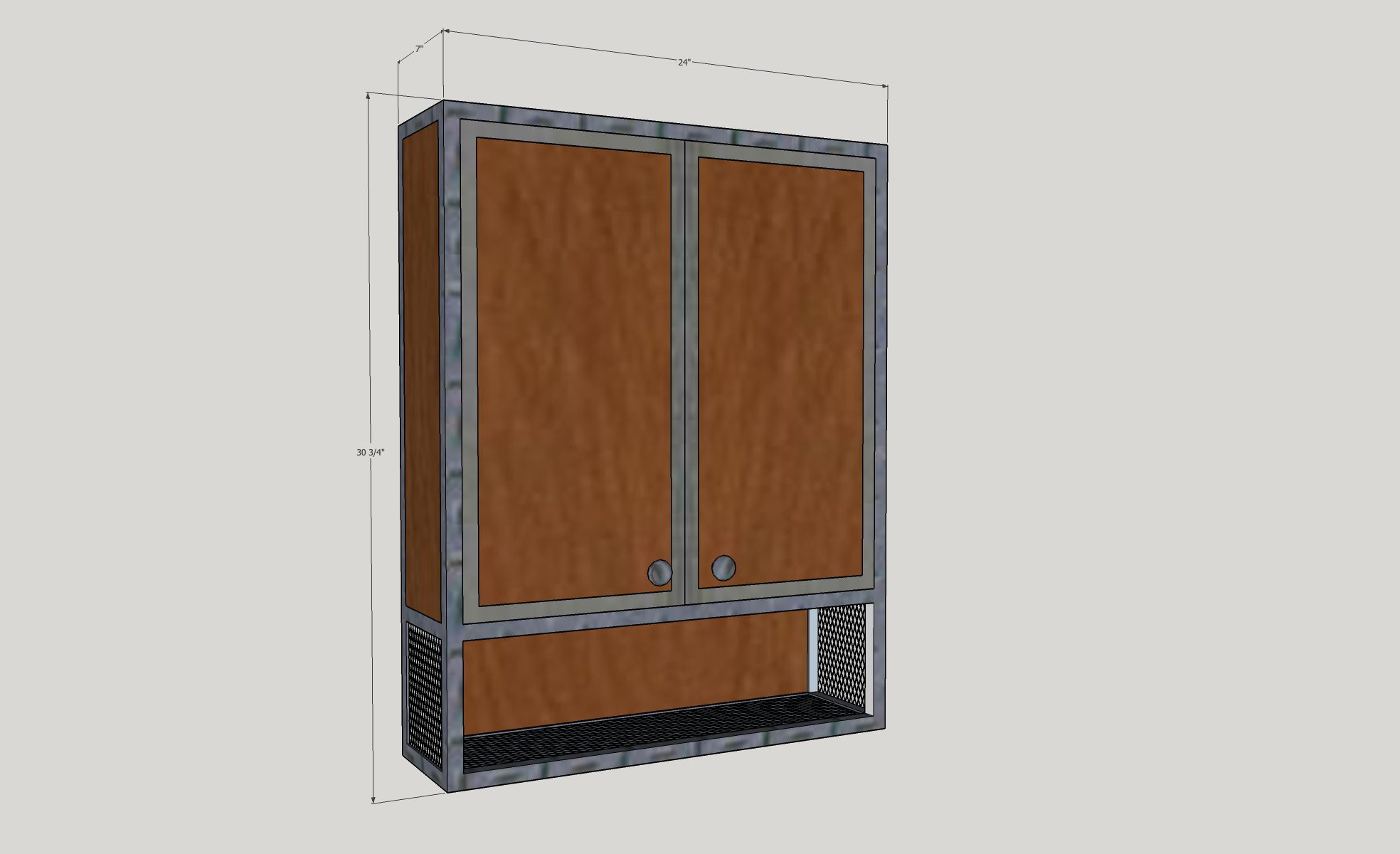

I had designed this small cabinet a while ago.

I had designed this small cabinet a while ago. When I find time, I try and make progress on it. I have the main frame finished, not it’s time to add some doors.

I saved hundreds of dollars by using my Primeweld TIG 225

I saved hundreds of dollars by using my @primeweld TIG 225 to make these locking clamps for my @weldtables welding table.

Arc Shot

I set up an old video camera on a tripod, put a welding shield in front of it, and was able to film this arc shot of a TIG weld. If the sensor in the camera had a better dynamic range, I think I would have been able to capture some more detail in the arc.

Bathroom Cabinet Project – Part 1

One of the projects I have been wanting to build for a couple years now is a new wall cabinet for our downstairs half bath. This room is very small, barely enough to fit a toilet and an extra small sink. There’s no storage at all. I thought about just buying a cabinet to go over the toilet, but I wanted to make something. Something from steel and old wood. I designed it in SketchUp.

I had the steel lying around for a while, I bought it before the workshop even existed. I put the Harbor Freight bandsaw to use cutting each of the pieces of angle and square tube.

For a cheap saw, I have it dialed in to cut very straight and accurate. I needed quite a few small pieces, needed to do a little bit of grinding to get the lengths just right.

I still need practice with the TIG welder, so I decided to use this project. Tacked everything together before finish welding with the TIG 225X.

Having the welding table and my homemade clamps made this a lot easier. I also used a set of Hobart corner clamps to get me started.

One of these days I will have to invest in some Fireball Tools squares, but they are very expensive. I might try designing a set and cutting them out on the water jet at CWRU.

I need to go get the rustic wood for the cabinet, and make the doors yet, and the figure out what I want to do for a patina. But with the Coronavirus lock down, I can’t really go anywhere.