How to sharpen a pencil.

.

.

.

Making’ chips!

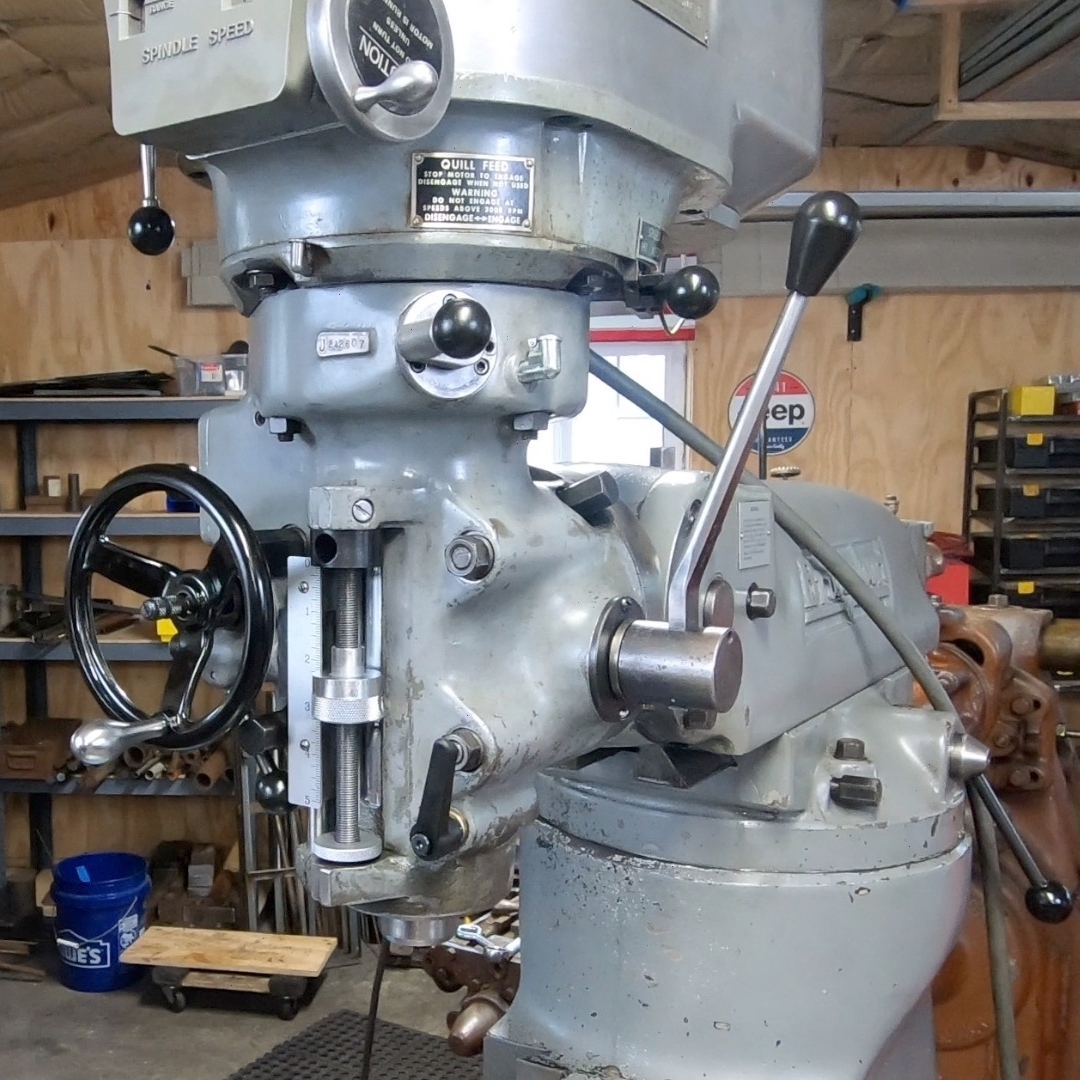

I completed the rehab of my Bridgeport vertical mill!

I completed the rehab of my Bridgeport vertical mill! I posted a video of the final pieces on my YouTube channel. I’m happy it is finally back together and I am able to put it to work!

The Series 1 Bridgeport I bought over a year ago is almost completely rebuilt.

The Series 1 Bridgeport I bought over a year ago is almost completely rebuilt. I’ve been making videos along the way. The latest is up on YouTube where I reassemble the top end gears, belts, lions and tigers, oh my!

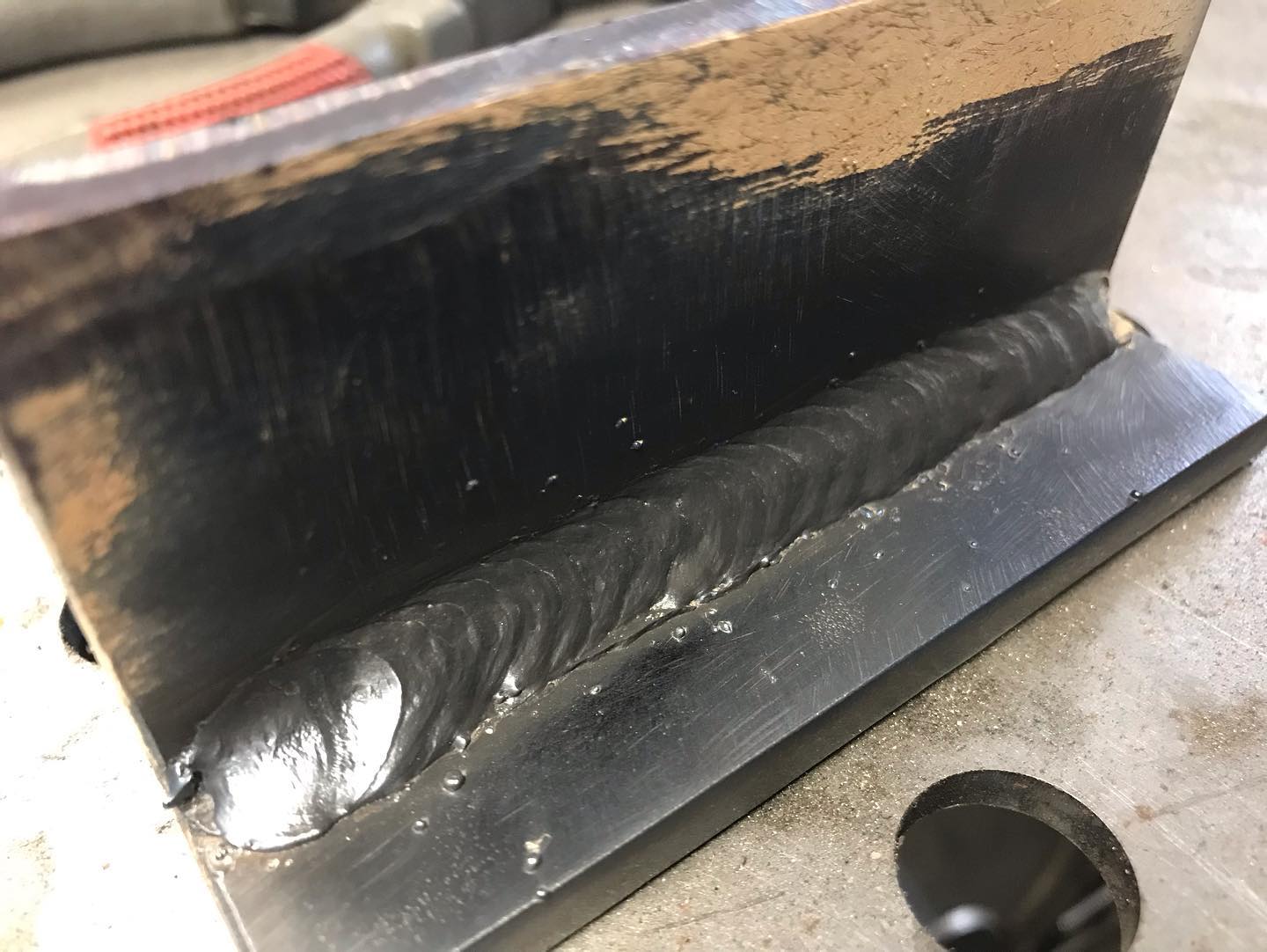

I think I have finally figured out the porosity issues

I think I have finally figured out the porosity issues I am having with my @hobartwelders 175 MIG welder when using ER70S-6 solid wire and C25 gas. That aluminum block in the second photo is the gun connector. It and the brass fitting on the gun, third and forth, had corroded so badly that I am sure there is an air leak. Trouble is, that part is no longer available. So until the Bridgeport is up and running so I can make a new one, going to have to resort to E71T-11 flux core. It welds nice, but the smoke and fumes is a pain when welding indoors.

.

.

.

.

Getting the saddle back on the knee

Getting the saddle back on the knee also necessitated putting the Bijur oil metering block and oil lines back in place.

The Bijur one-shot lubrication pump is back on the Bridgeport knee.

The Bijur one-shot lubrication pump is back on the Bridgeport knee. Over all, it was in decent shape and went back together easily.

The metering block for the Bridgeport mill.

The metering block for the Bridgeport mill. Spent some time cleaning all of these fitting and the main block. To replace this would be over $200 retail. I’d rather clean it.

.

.

.

.

.

This oiler for the Bridgeport mill was a mess.

This oiler for the Bridgeport mill was a mess. Caked with dried up oil and chips.

.

.

.

.

The knee to the Bridgeport mill has been installed back on the base.

The knee to the Bridgeport mill has been installed back on the base. Making progress!

.

.

.

.

.

.

.

.