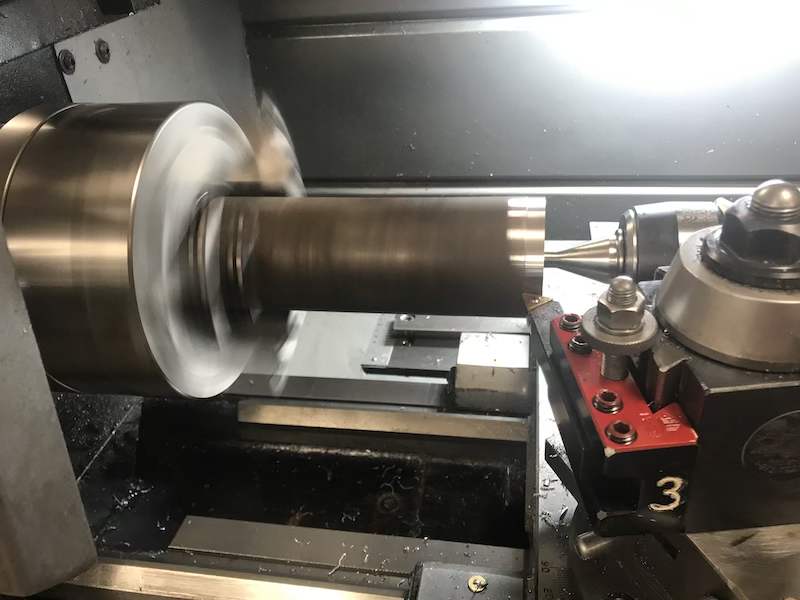

As I mentioned before, you really need to use a proper seal press in order to seat the new seals in the front differential. I could buy one for around $100. But this is something I really wanted to make. I was recently trained on how to safely use a metal lathe down at the CWRU Thinkbox, so I wanted to give it a try and make one.

I designed the part in Fusion 360.

I went to a local hardware store, and they just happened to have a drop of some 2.75″ round bar that was just the size I needed for $12. I took an afternoon on the lathe, and with some help, was able to turn the piece that I needed. It took a while, but I think it was well worth it. Not only did I learn a lot, but I saved a bunch of money!