Another Craig’s List score.

Making Adjusting Knobs for a South Bend Steady Rest (Part 2)

Continuing the restoration of the steady rest I bought for my 13″ South Bend lathe. It had many missing parts, including the adjustment knobs.

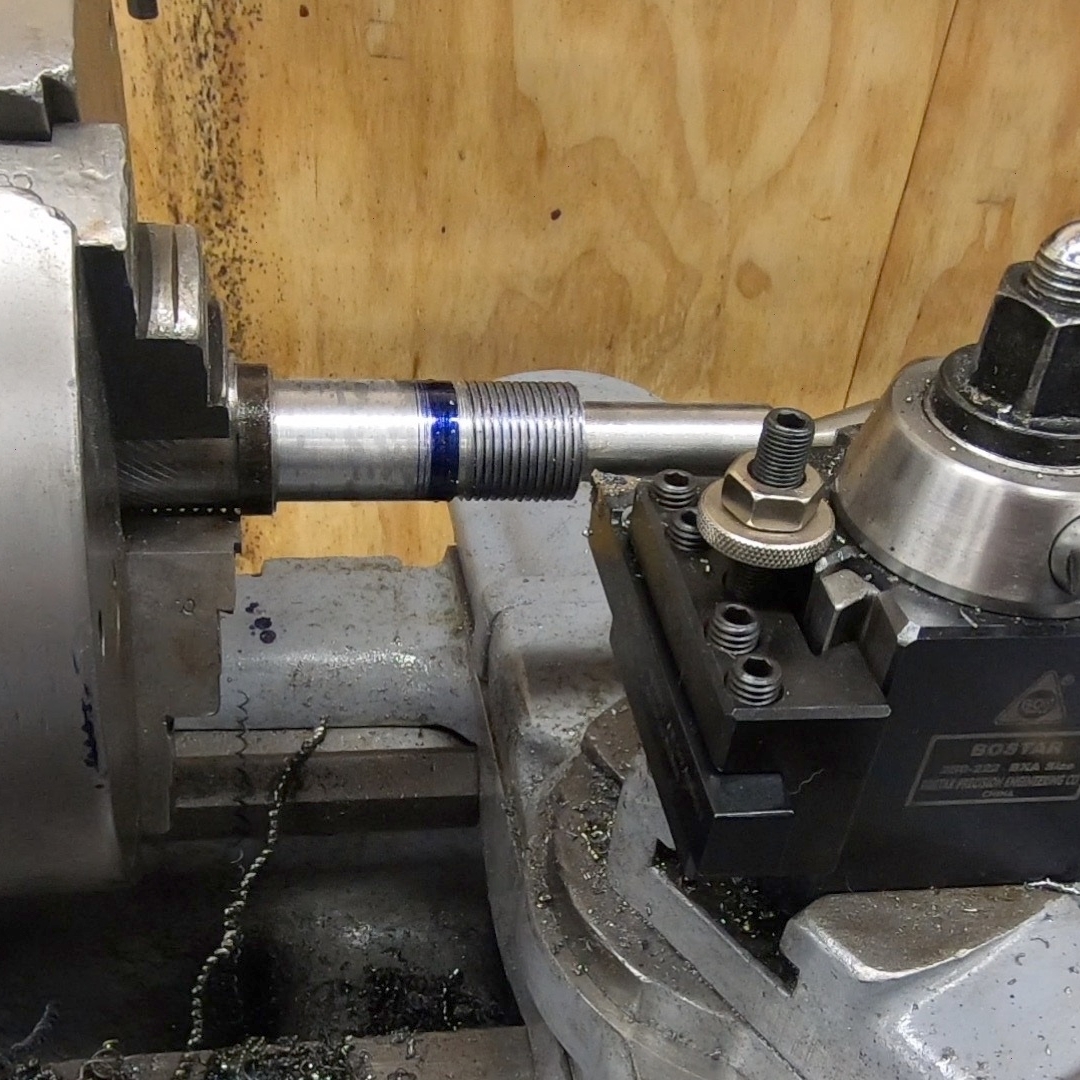

In this second part of making the knobs, I make a threaded arbor to facilitate the machining of the external features. I got to use one of my newly acquired thread pitch micrometers as well. One thing is for sure, I need to get better at nailing dimensions. I managed to overshoot just about every dimension on this part.

Back at making the missing parts for my steady rest.

Back at making the missing parts for my steady rest. I need a threaded arbor now to machine the external features on the adjustment knobs.

Who knew a guy with no legs could hit a grand slam out of the biggest ball park

Who knew a guy with no legs could hit a grand slam out of the biggest ball park ever. This guy is a hero.

Making Adjusting Knobs for a South Bend Steady Rest (Part 1)

Continuing the restoration of the steady rest I bought for my 13″ South Bend lathe. It had many missing parts, including the adjustment knobs.

In this first part of making the knobs, I get the stock cut to length and the internal features bored, reamed and threaded.

Purrty!

I bought about half of a steady rest for my South Bend 13″ lathe.

Making Jaw Adjustment Screws for a Steady Rest

I bought a steady rest for my South Bend lathe that needs some work. There are quite a few missing parts. Sure, I could buy every missing piece, but what’s the fun in that?

Tell me you had a great day in the shop without telling me you had a great day i

Tell me you had a great day in the shop without telling me you had a great day in the shop.

.

.

.